Our team will give you expert advice and guidance on the entire design and specification process including our extensive product range, including key considerations and optional extras and our dedicated bespoke service

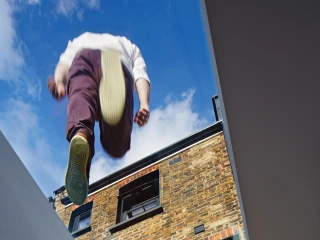

Integrate effortlessly into your building

The Glazing Vision Flushglaze Wall Abutted Rooflight is a minimalist fixed rooflight, boasting ‘frameless’ internal views, expertly designed to be structurally fixed to a wall or building on up to three sides.

The wall abutment detail is part of the Flushglaze framework and should be secured using suitable fixings, dependent on the structure being used. The rooflight should always be pitched away from the abutment detail to minimise the risk of water ingress. Once installed, the wall abutment frame should be flashed over to fully weatherproof it.

This detail is available on a number of Glazing Vision Flushglaze Rooflights, including solo and multi-part units, as well as walk on Flushglaze units. It is not currently available on Fire Rated Flushglaze Rooflights.

Key features

Optional extras

Discuss Your Project

Technical Specification Manager details not found

We're sorry, but we couldn't find a Technical Specification Manager for this area.

We’ll find the best person for you to speak to and be in touch within one working day.

Your TSM

Specification

Min span |

400mm |

Max span |

4131mm |

Min width |

400mm |

Max width |

4131mm |

Min upstand pitch |

3 degrees |

Max upstand pitch |

70 degrees |

Glazing Vision recommends a pitch of at least 5° for standard units.

Note that the minimum and maximum span, width and pitch are dependent on various factors, your technical sales advisor will be happy to advise on these. Further information on upstand requirements and product dimensions can be found on our website or by contacting your technical sales advisor.

Structural integrity of the Flushglaze Wall Abutted Rooflight is assured through the use of finite element analysis (FEA) and testing. Further information and specific performance details can be obtained from your Technical Sales Advisor.

The Flushglaze Wall Abutted Rooflight has been expertly designed with security as a priority - The product is tested to LPS2081 Issue 1:2015, approved by the Loss Prevention Certification Board (Cert/LPCB ref: 1347a) and Secured by Design.

To achieve Security Rating A, the inner pane must be at least 8.8 mm PVB laminated glass (two 4 mm thick panes separated by an 0.8 mm thick PVB interlayer).

To achieve Security Rating B, the inner pane must be at least 9.5 mm ionomer laminated glass (two 4 mm thick panes separated by a 1.5 mm thick ionomer interlayer).

Please contact our team if you have off-spec requirements for dimensions, glass or anything else, we’ll be happy to assist

Standards

Awards and certifications

Made in Britain

Glazing Vision rooflights are assembled on site in our rural Norfolk factory to ensure a high quality product - Made in Britain, trusted internationally.

ISO 9001 & ISO 14001

Glazing Vision operates to BSI ISO9001 and ISO14001 standards to ensure high quality rooflights

Secured by Design

Glazing Vision rooflights have been extensively tested and Secured by Design

Approved by the BBA

Glazing Vision rooflights have been approved by the BBA, with our Flushglaze Rooflight being the first flat rooflight ever approved by BBA

Approved by the LPCB

Glazing Vision Rooflights have been approved by the Loss Prevention Certification Board, allowing them to meet enhanced security requirements.

QualiCoat Applicator

Glazing Vision rooflights feature QualiCoat approved aluminum framework to ensure a high quality paint finish

Compare with other products

Access

Fire rated

Flat roof

Pitched roof

Residential

Ventilation

Walk on

Flushglaze Wall Abutted Rooflight

Flushglaze Fixed Rooflight

Flushglaze Fixed Multipart Rooflight

Flushglaze Circular Fixed Rooflight

Flushglaze Eaves Rooflight

Flushglaze Walk On Rooflight

Ridgeglaze Fixed Rooflight

Downloads

Specification

Manuals & guides

CAD & BIM

Frequently Asked Questions

Yes, all of our flat rooflights require an upstand, the minimum requirements for your upstand will be outlined in the product data sheets.

Our flat rooflights are measured by their External Kerb Dimensions, which refer to the distance between the external of the kerb to the external of the kerb on all sides.

The width of your kerb varies depending on the product chosen, for example our Fixed Flushglaze will require a minimum structural upstand of 75mm.

Select Glazing Vision flat rooflights can be installed at a pitch of up to 70 degrees such as the Flushglaze Fixed Rooflight, however if your roof pitch exceeds this, you will need to install a roof window.

If you opt for EnduroShield Easy Clean treatment, the chemically bonded treatment will keep the glass clean as any dirt will run off of the glass - An occasional clean with a non abrasive cleaning solution will ensure that the glass looks as good as new.

Overheating is a common concern with rooflights, however opting for a UV/Solar coating will ensure only light can come through the rooflight, reflecting infrared radiation. Another way to combat overheating is installing blinds as these will automatically create a shade for your rooflight.

Yes, all Glazing Vision rooflights are manufactured at our in-house factory in rural Norfolk, this ensures that every rooflight leaving the factory is of the highest quality.