Our team will give you expert advice and guidance on the entire design and specification process including our extensive product range, including key considerations and optional extras and our dedicated custom service

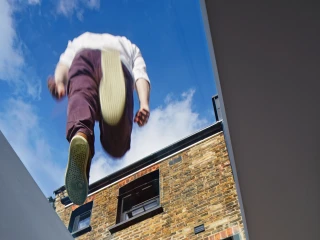

Elevate Your Space with Every Step

Whether you require a solution for your roof deck, balcony, or rooftop garden, the Glazing Vision Flushglaze Walkable Skylight provides the ultimate combination of durability and aesthetics for any property, allowing natural daylight to flow into the room(s) below without compromising usable space.

Constructed from toughened laminated glass, the Flushglaze Walkable Skylight is manufactured to withstand regular foot traffic in domestic applications with uniform loading’s of 1.5kN/m² and concentrated loading’s of 2.0kN in accordance with EN 1991-1-1-1:2002.

The Flushglaze Walkable Skylights are commonly installed using decking to achieve a flush finish with the skylight as a curb is still required.

Key features

Optional extras

Connect To An Expert

Contact a Technical Sales Manager

Please provide us with your project zipcode, and we will assign you to an experienced Technical Sales Manager

We’ll find the best person for you to speak to and be in touch within one working day.

Your TSM

Specification

Min Span |

16" |

Max Span |

169" |

Min Width |

16" |

Max Width |

169" |

Min curb pitch |

1/4” : 12” |

Max curb pitch |

32-7/8” : 12” |

Glazing Vision recommends a pitch of 1/4” : 12” for walkable units

Note that the minimum and maximum span, width and pitch are dependent on various factors, your technical sales advisor will be happy to advise on these. Further information on curb requirements and product dimensions can be found on our website or by contacting your technical sales advisor.

Structural integrity of the Flushglaze Walkable Skylight is assured through the use of finite element analysis (FEA) and testing. Further information and specific performance details can be obtained from your Technical Sales Advisor. The Walkable Flushglaze Skylight has been thoroughly tested and achieved the following classification results:

Size: 1829 mm (72”) span x 3982 mm (156-3/4”) width Pitch: 3° (5/8” : 12”)

Air Permeability - ASTM E283 - ±600 Pa (±12.53 psf)

Watertightness - ASTM E331 & E547 - 600 Pa (12.53 psf)

Wind resistance - ASTM E330 - ±2400 Pa (±50.13 psf) Serviceability & +4800 Pa (+100.25 psf), -3600 Pa (-75.19 psf) Safety

The Flushglaze Walkable Skylight has been expertly designed with security as a priority and has been certified by ICC (International Code Council) conforming to ICC-ES 2021 International Building Code & ICC-ES 2021 International Residential Code.

Please contact our team if you have off-spec requirements for dimensions, glass or anything else, we’ll be happy to assist

Awards and certifications

ICC Certified

Our Flushglaze Skylights have been certified by ICC (International Code Council) after extensive testing which allows the them to be utilized in Los Angeles projects.

AIA CES Lunch & Learn Providers

Glazing Vision provides architects with free, AIA CES Approved Lunch & Learns

Compare with other products

Access

Fire rated

Flat roof

Pitched roof

Residential

Ventilation

Walk on

Flushglaze Walkable Skylight

Flushglaze Fixed Skylight

Flushglaze Fixed Multipart Skylight

Flushglaze Wall Abutted Skylight

Flushglaze Eaves Skylight

Downloads

Specification

Manuals & guides

CAD & BIM

Frequently Asked Questions

Yes, you will still require a curb for the Flushglaze Walkable Skylight.

Glass can become slippery when wet therefore applying an anti-slip glass surface finish to the glass should always be considered to ensure the safety of all people using the walkable skylight. We commonly see sandblasted or fritted glass being specified for slip resistance.

The Glazing Vision Flushglaze Walkable Skylight is required to be installed at a pitch of of 1/4” : 12” to allow for water runoff.

Yes, the glass specified is Class 0 meaning it is specifically designed to withstand regular foot traffic.

No, you can not order just the glass from us as we assemble the entire skylight unit in our in house factory to ensure a high level of quality.

Lead times vary per product as they are carefully assembled and tested in-house, but your local Technical Sales Manager can advise you of our latest lead times.